When it comes to installing flooring and tiles, there are some very specific and often significant differences to be aware of.

To me the most obvious difference is that tiles themselves are strong, solid materials so anything they are bonded to must also be very strong and well braced, or must have a high degree of absorption against movement. They must also lie flat (the adhesives can help to create the flatness should a substrate have undulations), whereas a carpet or a vinyl, for example, can easily perform if the floor has undulations and levels of bounce and movement.

This enables products for tiling to be much more controlled with regard to performance and classification. We don’t really have this in flooring as the substrates themselves are often the biggest variable on site and therefore products need to cope with these variables.

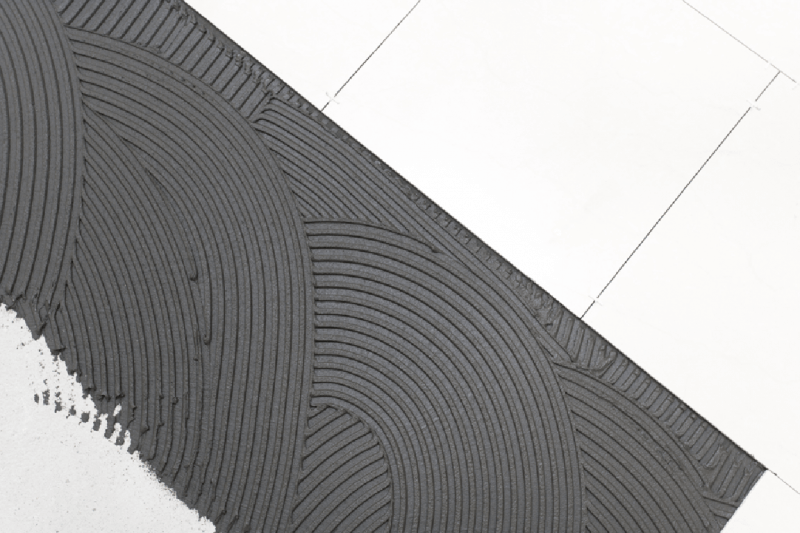

Most subfloor manufacturers will use cements within their product portfolio and so a natural synergy is to develop cementitious products for other uses. Sometimes this can be screeds, sometimes road repairs and rapid setting concretes but more often than not it can be cementitious tiling products. Cements work in basic terms by reacting with water to cure, harden and strengthen up. The polymers added to them give improved adhesion and, in loose terminology, a bit of flexibility. The key is that they react rather than dry out.

The cement products in tiling fall into two basic categories, namely grouts and adhesives. The tiling industry has classifications (referred to as EN 12004, 12002 and 13888) and specific tests to determine if a product is suitable for particular application, so in essence it is well defined where they can be used. I won’t go into the meaning and testing behind these in this article as it is in itself a mini science. The classifications help a lot in selecting the right products for the right installation on the right substrate.

With regard to adhesives, the characteristics can vary from a standard setting adhesive, to a fast setting adhesive, to a deformable adhesive. As you move through the various product specification variables you can take on a range of tasks such as adhering large porcelain tiles, or bonding small mosaics, or deep adhesive beds for variable depth stone tiles. Unlike most subfloor preparation products and tiling adhesives, grouts themselves will actually be visible after use, so colourfastness and resistance to moisture is critical too. Sometimes chemical resistance is required and can lead to using more specialist grouts such as epoxy products.

The real difference between tiling and flooring comes when using ready mix tiling adhesives, or as they’re known in the market, dispersion adhesives. Although you may think of them as typically being used in the DIY market, there are some real advantages in practical terms as long as the understanding of how they work and where they can be used is appreciated. The classification system stands here also with slip resistance, moisture tolerance and open time being typical variables. The major advantage is the fact that the product is ready to use and does not require mixing, so you don’t have to worry about finding water to mix with, preventing dust or cleaning tools.

However, don’t look at them as an alternative to laying tiles onto a floor. The bonding process relies on evaporation of the moisture and so the strength of bond takes time to build up. You can easily disturb and weaken the bond with foot traffic so always use the cementitious systems on a floor.

They can however be used to some extent on walls. This is because once the initial bond has taken place on the wall there is unlikely to be any disruption to the bond and the strength can improve over time. Again, there are limitations as to when a dispersion adhesive may be used. This stems from the fact that after initial set the moisture in the adhesive needs to dry out over time. This can happen through the tile if it is a ceramic type with a “biscuit” back or through the adjacent grouting lines. Look for products that have good slip resistance, and if you’re considering using in a high humidity area, look for one with good water resistant claims.

Avoid using with larger tiles or highly vitrified and low porosity tiles (i.e. porcelain, glass etc.) where the rate of loss of moisture can be very slow and therefore the bond is very poor.

After all, if you find yourself in these situations you have your good old friend ‘Mr Cementitious’ to turn to.

Written by Martin Cummins