“How do you know that?” This is a question I asked (a lot!) when I started out in the flooring trade, and it was the one question that my bosses didn’t mind me asking again and again. The reply was always the same; “let me show you.” Even back then with the lack of formal training available within the industry, the importance of knowledge transfer was obvious.

Historically, the need to mechanically prepare a floor was rare, one product seemed to do it all with inevitably long drying times leading to extended completion times. It is now evident that without a clear understanding of the limitations of flooring systems, it is impossible to select or recommend the appropriate products to make the job run smoothly, and difficult to predict potential issues in the future.

The flooring trade of the 21st century must keep up with the ever-evolving technology behind subfloor preparation products and flooring adhesives – the expectation is that contractors must be amateur scientists as well as professional tradespeople.

“The expectation is that contractors must be amateur scientists as well as professional tradespeople”

Take calcium sulphate screeds as an example, which are now commonplace on new build projects. The ability to identify these screeds and understand how they react with cement-based smoothing compounds is vital to ensure the correct system of preparation products is used to safeguard the long-term performance of a flooring installation. Without this knowledge, it’s likely the installer will find out the hard way on a client’s job, leading to an embarrassing call back and expensive repairs.

There is thankfully now an abundance of flooring training available, covering everything from basic application skills through to recognised trade qualifications. If you are open to learning and developing your skills and knowledge, then there will be a training course to suit you.

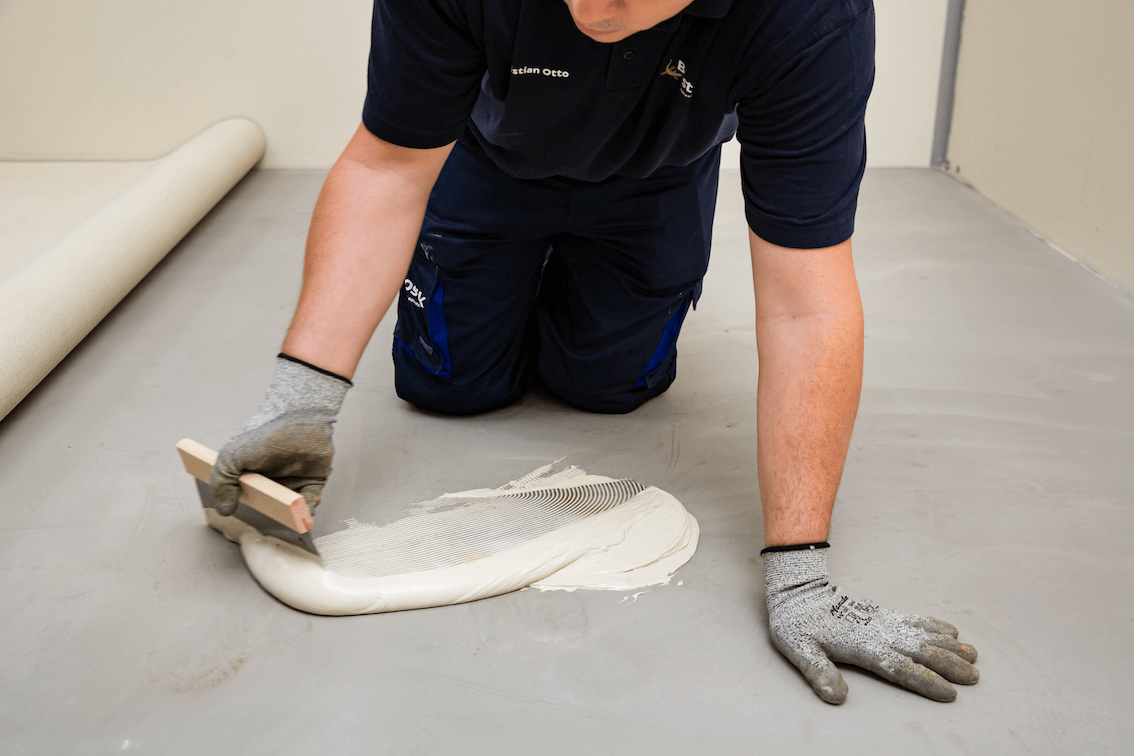

These courses are usually a mix of theory and practical sessions, allowing attendees to use their newly found skills and develop them with the support of experienced trainers in a safe and encouraging environment. Having the chance to try out new products before you go on a job promotes confidence, allows you to achieve a better finish and, importantly, allows you to provide a professional performance in front of clients.

“Training isn’t only about ensuring you don’t make mistakes on the job”

However, training isn’t only about ensuring you don’t make mistakes on the job, it also provides the opportunity to upskill for financial gain. For example, installers who may have previously specialised in installing textile coverings have the opportunity to upskill and benefit from the financial rewards of fitting LVT, which has seen a huge rise in popularity in recent years.

According to the CITB, almost 225,000 extra workers will be needed to meet UK construction demand by 2027, so it’s crucial the industry not only attracts new talent, but also retains the people within it to prevent that number from growing in the future.

Manufacturers are the designers of products and systems that play a key role in moving the industry forward. So, when offered the opportunity to attend a course at a manufacturer’s training facility, my advice would always be to say “yes” regardless of your level of experience. By working together, we can achieve “better results through knowledge” and develop a more cohesive, forward thinking flooring industry.

Written by Paul Sycamore, Training Manager at Bostik UK